- Home Page

- Company Profile

-

Our Products

- Heat Resistant Paint

- Heat Resistant High Temperature Coatings

- Heat Resistant Aluminium Paint

- Furnace Heat Resistant Paints

- UGAM Heat Resistant Paint

- UGAM Heat Resistant High Temperature Coatings 1800 WB

- UGAM Furnace Heat Resistant Paints 1200 SB

- UGAM Heat & Oil Resistant Paint

- UGAM Heat Resistant Paint 400

- UGAM Heat Resistant Aluminium Paint

- UGAM Heat Resistant Coatings 600

- UGAM Heat Resistant High Temperature Paints 600 EPSI

- UGAM Heat Resistant & Thermal Insulation Paint For 160 Deg C

- UGAM S I Thermal Insulation Coating

- Thermal Insulation Coating - Energy Saving Coating

- Heat Resistant Paint For 400 Deg C

- Heat Resistant and Thermal Insulation Paint For 160 Deg C

- UGAM Heat Resistant & Thermal Insulation Paint For 1200 Deg C- SB

- UGAM Heat Resistant & Thermal Insulation Paint For 1200 Deg C -WB

- UGAM Heat Resistant & Thermal Insulation Paint For 1800 Deg C -WB

- UGAM Heat Resistant & Thermal Insulation Paint For 600 Deg C EPSI

- UGAM Heat Resistant & Thermal Insulation Paint For 400 Deg C

- UGAM Heat Resistant & Thermal Insulation Paint For 160 Deg C

- UGAM Heat Resistant & Thermal Insulation Paint For 600 Deg C

- Fireproof & Flameproof Coating

- Fire Retardant Paints

- fire proof paints

- Electrical Cables Fireproof Coatings

- Fire Resistant Coatings

- Fire Protective Epoxy Intumescent Coatings

- Fireproof / Flameproof Material

- UGAM Fire Retardant Coating for Wood

- UGAM Vermiculite Fireproof Coatings for Steel structure

- UGAM Electrical Cables Fireproof Coatings

- UGAM Fire Retardant Paint for Interior Steel Structure

- UGAM Fire Protective Epoxy Intumescent Coating for Exterior Steel Structure

- UGAM Clear Flame Retardant Coating for Wood, Fabric, Paper & etc

- UGAM Fire Retardant Paints for Wall, Gypsum and Interior Steel structure

- UGAM Fire Retardant Coating for Wood

- Industrial Painting & Cleaning Services

- Industrial Road and Floor Marking Paints

- Paint and Allied Products

- Solar Heat Reflective Paint

- UGAM Heat Reflective Paint

- UGAM Insulmix Epoxy Heat Reflective Paint

- UGAM Insulmix Heat Reflective Paint

- UGAM Cool Roof Paint

- Insulmix Heat Reflective Paint

- UGAM Insulmix Epoxy Heat Reflective Paint

- UGAM Heat Resistant & Thermal Insulation Paint For 400 Deg C

- UGAM Fire Protective Epoxy Intumescent Coating for Exterior Steel Structure

- UGAM Insulmix Heat Reflective Paint

- UGAM Heat Resistant Paint 400

- Corrosion Resistant Coatings

- Waterproof Paints & Coatings

- Energy Saving Conduction, Convection & Radiation

- LPG Bullets Coating

- Anti IR Paint

- Acrylic Sealant

- Heat Resistant Paint

- Awards

- Contact Us

V.C.T.I. Heat Resistant and Thermal Insulation Paint

Product Details:

X

V.C.T.I. Heat Resistant and Thermal Insulation Paint Price And Quantity

- 10 Kilograms

V.C.T.I. Heat Resistant and Thermal Insulation Paint Trade Information

- 6000 Kilograms Per Month

- 2-8 Days

- All India

Product Description

UGAM VCTI COATING

DESCRIPTION:

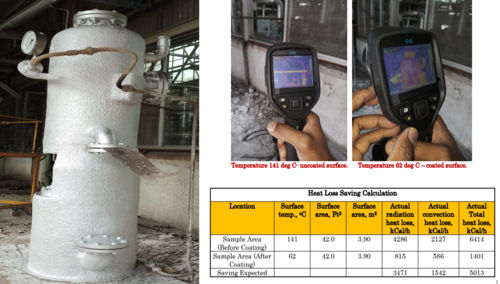

1) The Product is mainly used for reducing the surface temperatures of hot surfaces like Exterior of boilers.

2) When there is heavy heat losses through boiler surfaces, UGAM V C T I coating is the best solution to arrest the same.

3) Approximately 30 to 50 mm thick coating is to be applied depending upon the surface temperature. Our technical team will provide you the guidance on the same.

4) This is also used for reducing the surface temperatures of steam lines, hot water lines, hot gasses lines, hot oil lines etc.

5) The pipelines are coated over with UGAM V C T I coating to bring the temperatures to ambient.

6) This also provides energy saving and increased efficiency due to blocking of heat losses.

7) This is ideally suitable for reducing surface temperatures of furnaces and tobring it to near to ambient.

8) The Product is mainly used for reducing the surface temperatures of hot surfaces like Exterior of boilers. When there is heavy heat losses through boiler surfaces, UGAM V C T I coating is the best solution to arrest the same. Approximately 30 to 50 mm thick coating is to be applied depending upon the surface temperature. Our technical team will provide you the guidance on the same.

9) This is also used for reducing the surface temperatures of steam lines, hot water lines, Hot gasses lines, hot oil lines etc. The pipelines are coated over with UGAM V C T I Coating to bring the temperatures to ambient. This also provides energy saving and Increased efficiency due to blocking of heat losses.

10) This is ideally suitable for reducing surface temperatures of furnaces and to bring it to near to ambient.

Surface Preparation:

1) UGAM V.C.T.I. can be applied to bare steel, provided that the surface is clean, free from oil, dust, loose mill scale, loose rust, or any other contamination. The contractor is responsible for ensuring that the steel surfaces are in a suitable state to receive UGAM V.C.T.I.

2) Cleaning can be effected by using brushes, industrial brushes, industrial vacuum cleaners etc. Oils and greases can be removed by steam cleaning or water jetting using suitable detergent solutions.

3) The pH value of UGAM V.C.T.I. is 12 at the time of application. This has the advantage of imparting a degree of corrosion protection to bare steel members, provided that the sprayed coating remains dry in use, as will usually apply for internal applications. In the case of UGAM V.C.T.I. External Grade, which is going to be permanently exposed to the elements, in addition to any protective treatment to the steel on erection, a final protective paint coating will be required over the completed UGAM V.C.T.I. Layer. In any case, we suggest application of UGAM V C PRIMER to bare steel before application of UGAM V.C.T.I.

4) A "prick-up" coat is recommended to all painted surfaces, however, certain paints, e.g. alkyd based primers, can be degraded by the alkalinity of cement, and where surfaces have been so painted it is recommended that the advice of the paint manufacturer should be obtained. If this advice cannot be obtained, or if there is any doubt as to the suitability of the given paint, the painted surface should ALWAYS be treated with a coating of UGAM V C PRIMER.

5) On galvanized steel an etch primer should be used, followed by a coat of UGAM V C PRIMER.

6) Aluminium surfaces are alkali sensitive and require treatment with an etch primer, again followed by a coat of UGAM V C Primer.

7) Concrete surfaces should be cleaned by the removal of dust, and all traces of oil and grease, including any mould release agents. If painted, follow the specification in 3.4 above.

8) Before the commencement of spraying, complete any necessary masking to protect specific areas from overspray.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free