- Home Page

- Company Profile

-

Our Products

- Heat Resistant Paint

- Heat Resistant High Temperature Coatings

- Heat Resistant Aluminium Paint

- Furnace Heat Resistant Paints

- UGAM Heat Resistant Paint

- UGAM Heat Resistant High Temperature Coatings 1800 WB

- UGAM Furnace Heat Resistant Paints 1200 SB

- UGAM Heat & Oil Resistant Paint

- UGAM Heat Resistant Paint 400

- UGAM Heat Resistant Aluminium Paint

- UGAM Heat Resistant Coatings 600

- UGAM Heat Resistant High Temperature Paints 600 EPSI

- UGAM Heat Resistant & Thermal Insulation Paint For 160 Deg C

- UGAM S I Thermal Insulation Coating

- Thermal Insulation Coating - Energy Saving Coating

- Heat Resistant Paint For 400 Deg C

- Heat Resistant and Thermal Insulation Paint For 160 Deg C

- UGAM Heat Resistant & Thermal Insulation Paint For 1200 Deg C- SB

- UGAM Heat Resistant & Thermal Insulation Paint For 1200 Deg C -WB

- UGAM Heat Resistant & Thermal Insulation Paint For 1800 Deg C -WB

- UGAM Heat Resistant & Thermal Insulation Paint For 600 Deg C EPSI

- UGAM Heat Resistant & Thermal Insulation Paint For 400 Deg C

- UGAM Heat Resistant & Thermal Insulation Paint For 160 Deg C

- UGAM Heat Resistant & Thermal Insulation Paint For 600 Deg C

- Fireproof & Flameproof Coating

- Fire Retardant Paints

- fire proof paints

- Electrical Cables Fireproof Coatings

- Fire Resistant Coatings

- Fire Protective Epoxy Intumescent Coatings

- Fireproof / Flameproof Material

- UGAM Fire Retardant Coating for Wood

- UGAM Vermiculite Fireproof Coatings for Steel structure

- UGAM Electrical Cables Fireproof Coatings

- UGAM Fire Retardant Paint for Interior Steel Structure

- UGAM Fire Protective Epoxy Intumescent Coating for Exterior Steel Structure

- UGAM Clear Flame Retardant Coating for Wood, Fabric, Paper & etc

- UGAM Fire Retardant Paints for Wall, Gypsum and Interior Steel structure

- UGAM Fire Retardant Coating for Wood

- Industrial Painting & Cleaning Services

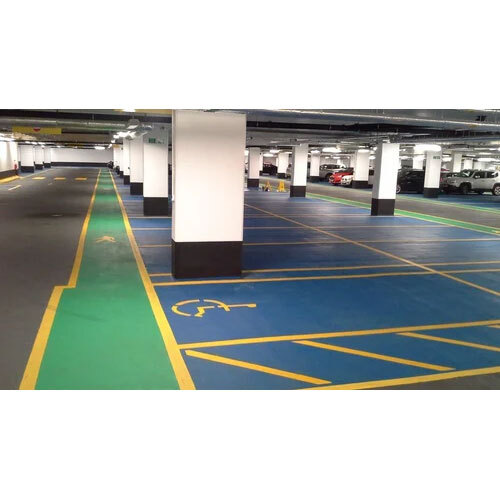

- Industrial Road and Floor Marking Paints

- Paint and Allied Products

- Solar Heat Reflective Paint

- UGAM Heat Reflective Paint

- UGAM Insulmix Epoxy Heat Reflective Paint

- UGAM Insulmix Heat Reflective Paint

- UGAM Cool Roof Paint

- Insulmix Heat Reflective Paint

- UGAM Insulmix Epoxy Heat Reflective Paint

- UGAM Heat Resistant & Thermal Insulation Paint For 400 Deg C

- UGAM Fire Protective Epoxy Intumescent Coating for Exterior Steel Structure

- UGAM Insulmix Heat Reflective Paint

- UGAM Heat Resistant Paint 400

- Corrosion Resistant Coatings

- Waterproof Paints & Coatings

- Energy Saving Conduction, Convection & Radiation

- LPG Bullets Coating

- Anti IR Paint

- Acrylic Sealant

- Heat Resistant Paint

- Awards

- Contact Us

Showroom

The Heat Resistant Paints are made for their effective coatingand can deal with the specific temperature range. The paints are used to coat Vehicle Silencers, Chimneys, Exhaust Chambers, and Pipelines, etc.

The Heat Resistant & Thermal Insulation Coating are the paints, included with ceramic microspheres as well as special additives. Their application is required to reduce the heat losses and provide good finish to the external cladding of space shuttle.

Fireproof & Flameproof Materials are the coatings, made to retard theflame. Their application bring the effect of insulation coating. The unique coating provided by these provide a matte finish and thus are used for exhaust systems, jet enginesand aerospace industry.

Offered high-quality Paint and Allied Products are demanded for chemical industry. These can be used as the effective and safe to use water proof coating that can also fill the cracks.

Corrosion resistant coatings we deal in are made to protect the metal components. These can evade the degradation caused bysalt spray, oxidationand moisture. The coatings are made toresist the harsh effect of several industrial chemicals.

Energy Saving Conduction, Convection & Radiation coatings are the paints, which serve as the outstanding waterproofing solutions. These are apt to be applied on the roof and terrace.

The LPG Bullets Coatings are the industrialgradepaints, used for the external coating of LPG Bullets and buried fuel tanks. These are made to resist the damage during their installation, handlingand storage. The paints are made topreservethe constant electrical resistivity.

Offered Anti IR Paints are made for the absolute protection of buildings. These are applicable for satellites and UAVs, thermal targeting systems, surveillance systems and many others. These special types of paints are included with ceramic microspheres.

Call Me Free

Call Me Free